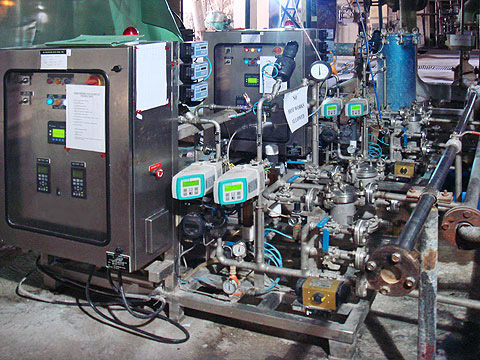

The Deltablend emulsification system enables ASA (alkenyl succinic anhydride) sizing, and is designed to produce alkaline emulsions for single, multiple or continuous direct feeds into the papermaking machine.

It processes ASA in either cooked, wet end or cold water-soluble starch, and produces highly stable emulsions with median ASA particles of between 0.5 to 1.25 microns. Particle size distribution is controlled via fully automated turbine pumps and fixed-pressure regulators that monitor the delicate balance between starch and ASA concentration levels for high-quality end products.

| Features | |

|---|---|

| ASA flow rate of up to 300 litres per hour | |

| Starch flow rate of up to 3,000 litres per hour | |

| Optional accessories: | Storage tank Starch dosing pump skid Plate Heat Exchanger |